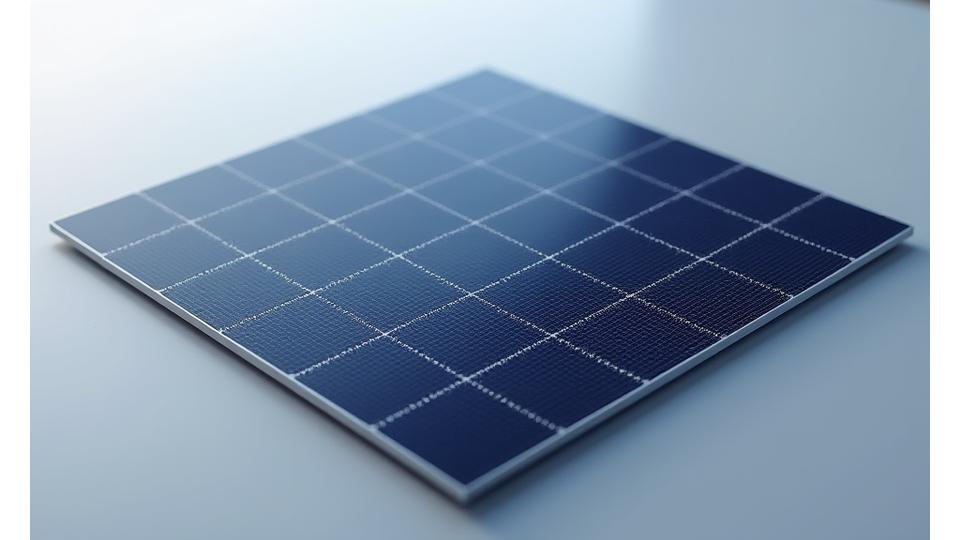

Premium Solar Panels Manufactured in Los Angeles

When project success depends on reliable supply chains and Buy America compliance, SolsticeForge's Los Angeles manufacturing facility delivers the high-efficiency solar panels that utilities and EPCs trust.

450W+ High-Efficiency

Monocrystalline Modules, 21%+ Cell Efficiency

25-Year Bankable Warranty

Backed by Comprehensive Insurance

Buy America Compliant

Full Supply Chain Transparency

100 MW Annual Capacity

Scalable Manufacturing Lines

Module Specifications & Performance Data

SolsticeForge manufactures a range of high-efficiency PV modules designed for diverse applications, from utility-scale power plants to distributed commercial rooftop installations. Our panels are engineered for peak performance and durability in varied climates.

Key Electrical Characteristics (STC)

Our Titan 450 Series modules set the standard for high-wattage performance, making them ideal for projects prioritizing output and efficiency.

- Nominal Power (Pmax): 450W

- Module Efficiency: 21.3%

- Open Circuit Voltage (Voc): 50.1V

- Short Circuit Current (Isc): 11.3 A

- Power Tolerance: 0 ~ +5W

Mechanical Specifications

- Dimensions (L x W x H): 2108 x 1048 x 35 mm

- Weight: 24.8 kg

- Snow Load: 5400 Pa

- Wind Load: 2400 Pa

Key Electrical Characteristics (STC)

The Aegis 430 Series offers an excellent balance of performance and adaptability, making it an ideal choice for diverse commercial and industrial installations.

- Nominal Power (Pmax): 430W

- Module Efficiency: 20.8%

- Open Circuit Voltage (Voc): 49.5V

- Short Circuit Current (Isc): 10.9 A

- Power Tolerance: 0 ~ +5W

Key Electrical Characteristics (STC) @ 10% Albedo

Our Sentinel Bifacial modules maximize energy harvesting, ideal for ground-mounted systems and specific installations where rear-side irradiance capture provides significant gains.

- Nominal Power (Pmax): 460W (Front) / Up to 598W (Bifacial)

- Module Efficiency: 21.8% (Front)

- Bifaciality Factor: 80 ± 5 %

- Open Circuit Voltage (Voc): 50.5V

- Short Circuit Current (Isc): 11.5 A

Need a custom solution or more detailed performance curves? Contact our engineering team.

Rigorous Quality Control at Every Step

At SolsticeForge, quality is non-negotiable. Our Los Angeles facility integrates advanced automation with meticulous human oversight to ensure every module meets and surpasses international standards and client expectations. We build reliability into every stage of production.

1. Incoming Material Inspection

Every raw component, from silicon cells to aluminum frames, undergoes multi-point inspection and testing to verify purity, integrity, and compliance with our strict specifications before entering production.

2. In-Line Process Monitoring

Automated optical inspection systems and human technicians continuously monitor lamination, soldering, and framing processes, ensuring precision at every critical juncture. Real-time data drives immediate adjustments.

3. Final Product Testing

Every finished module undergoes Electroluminescence (EL) testing, flash testing for power output verification, and detailed visual inspection to guarantee flawlessness and rated performance.

4. Third-Party Certifications

Beyond our internal protocols, SolsticeForge modules hold certifications from leading global bodies including IEC 61215, IEC 61730, and UL 1703, assuring compliance with the highest safety and performance benchmarks.

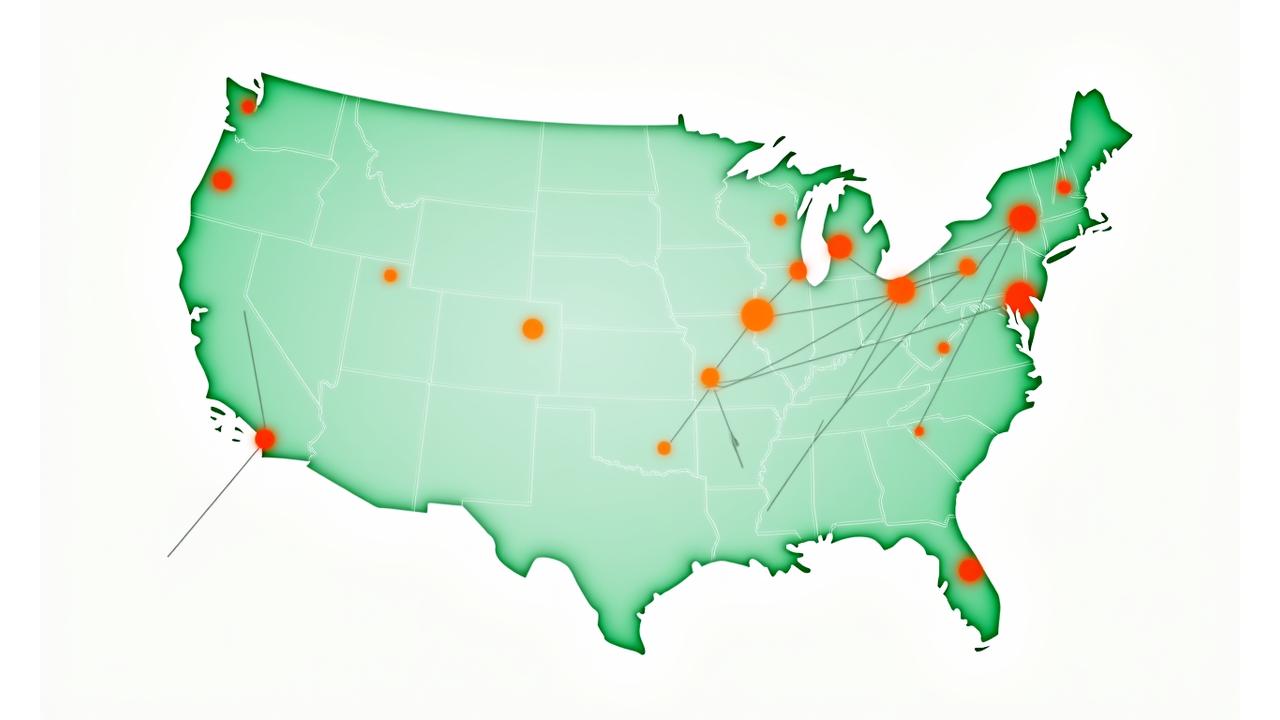

Domestic Supply Chain Advantage

In an increasingly complex global landscape, SolsticeForge offers unparalleled supply chain reliability, anchored by our Los Angeles manufacturing hub. We prioritize domestic sourcing and forge robust partnerships to ensure consistent material flow and expedited delivery, providing you with a critical advantage for time-sensitive projects and demanding procurement standards.

-

✓

Buy America Act Compliance: Our modules meet stringent domestic content requirements, enabling your projects to qualify for critical incentives and mandates.

-

✓

Strategic U.S. Partnerships: Collaborations with leading American suppliers for polysilicon, glass, and frames reduce geopolitical risks and transportation delays.

-

✓

Transparent Traceability: Full visibility into our supply chain, from raw materials to finished goods, ensures ethical sourcing and quality control.

25-Year Bankable Warranties

Investing in SolsticeForge solar panels means investing in long-term peace of mind. Our industry-leading 25-year linear power output warranty and 12-year product workmanship warranty are backed by comprehensive insurance and global financial strength, ensuring the bankability and resilience of your solar assets.

Linear Power Output Warranty

We guarantee that your SolsticeForge modules will produce at least 98% of their nominal power in the first year, degrading by no more than 0.55% annually thereafter. By year 25, our modules are guaranteed to produce at least 84.8% of their original rated power.

- •Year 1: 98% minimum power output

- •Years 2-25: Degradation no more than 0.55% per year

- •Year 25: 84.8% minimum power output

Product Workmanship Warranty

SolsticeForge warrants that our modules are free from defects in materials and workmanship under normal application, installation, use, and service conditions for a period of 12 years from the date of purchase.

- •Covers defects in materials and manufacturing

- •12 years comprehensive coverage

- •Industry-standard terms and conditions

Backed by Leading Insurance Providers

Our robust warranties are further strengthened by backing from a consortium of reputable international insurance providers. This financial safeguard ensures that your investment is protected, offering unparalleled security and confidence for long-term project viability and financing.

Production Capabilities & Lead Times

SolsticeForge's Los Angeles facility is engineered for scale and efficiency. With a robust 100 MW annual production capacity, we are equipped to support both large-scale utility projects and high-volume commercial deployments, delivering modules on schedule to meet your project milestones.

Scalable Capacity to Meet Demand

Our current production lines boast an annual output of 100 Megawatts, strategically designed for modular expansion. This flexibility allows us to swiftly scale operations to accommodate increasing market demand or specific, large-volume client requirements, ensuring your project timelines are consistently met.

- •100 MW current annual production

- •State-of-the-art automated production lines

- •Rapid expansion capabilities for future growth

Typical Lead Times

Our efficient manufacturing processes and reliable supply chain enable competitive lead times for domestic delivery.

| Order Quantity | Typical Lead Time (Ex-works LA) |

|---|---|

| Up to 1 MW | 3-4 Weeks |

| 1 MW - 5 MW | 4-6 Weeks |

| 5 MW - 20 MW | 6-8 Weeks |

| 20 MW+ | Custom Schedule (Contact Sales) |

For specific project requirements or to discuss reservation of capacity, please reach out to our sales team.

Proven Performance in the Field

Our commitment to quality and American manufacturing has earned the trust of leading utility companies, commercial developers, and municipal entities across the nation. Explore how SolsticeForge modules deliver measurable impact for demanding projects.

Case Study: Southern California Utility Grid Enhancement

Deployment of 50 MW of SolsticeForge Titan 450 modules for a major utility provider in the Mohave Desert. Project completed 3 weeks ahead of schedule, exceeding initial performance models by 1.5% in its first year of operation.

"SolsticeForge's domestic supply chain was a game-changer for meeting our strict 'Buy America' requirements and incredibly tight deadlines. The modules' performance has been stellar."

— Emily Rodriguez, Project Director, Desert Sun Power Corp.

Case Study: Major Retailer Distribution Center

A 2.5 MW rooftop installation for a national retail chain's flagship distribution center in Fontana, CA, utilizing Aegis 430 Series modules. The rapid deployment allowed the client to achieve significant energy cost savings months earlier than projected.

"The quality and fast delivery from SolsticeForge streamlined our entire project. Their team's support ensured a seamless integration and immediate operational benefits."

— David Chen, Head of Sustainability, Evergreen Logistics Group

Case Study: City of Santa Monica Civic Center Solar

Installation of a 750 kW solar canopy system featuring SolsticeForge Sentinel Bifacial modules over the Santa Monica Civic Center parking lot. The bifacial design maximized energy yield, supporting the city's ambitious carbon reduction goals.

"For our public infrastructure project, reliability and domestic origin were paramount. SolsticeForge delivered on all fronts, providing high-performing panels and invaluable technical support."

— Maria Sanchez, City Engineer, Santa Monica Public Works

Request Volume Pricing & Technical Support

Ready to power your next project with high-efficiency, American-made solar panels? Fill out the form below to receive a customized quote, access detailed technical specifications, or connect directly with our engineering and sales teams for project-specific guidance.