Precision Wind Components Made in America

When wind project success demands precision-engineered components and reliable domestic supply, SolsticeForge's advanced manufacturing delivers the quality and timeline certainty that OEMs and developers require.

Combining aerospace-grade precision with renewable energy expertise, we support America's growing onshore wind capacity.

Discuss Your Component Needs Explore Our Portfolio80%+

Domestic Material Content

Tier 1 Certified

Quality Systems

180m+

Blade Manufacturing Capability

Complete Component Manufacturing Portfolio

SolsticeForge is your comprehensive partner for critical wind turbine components, delivering unmatched precision and reliability across the full spectrum of subassemblies required for modern wind energy systems.

Advanced Composite Blades

We manufacture wind turbine blades with custom length and design specifications, leveraging patented composite materials and robotic winding for optimal performance and longevity. Blades up to 180 meters are within our current production capabilities.

- Custom Length & Aerodynamic Profiles

- High-Strength, Lightweight Composites

- Integrated Lightning Protection Systems

Nacelle Housings & Assemblies

SolsticeForge produces lightweight, durable nacelle housings and integrates complex internal component assemblies, including custom gearboxes and cooling systems. Our precision manufacturing ensures seamless integration and operational reliability.

- Modular Design for Easy Integration

- Optimized Aerodynamics & Structural Integrity

- Full System Pre-Assembly & Testing

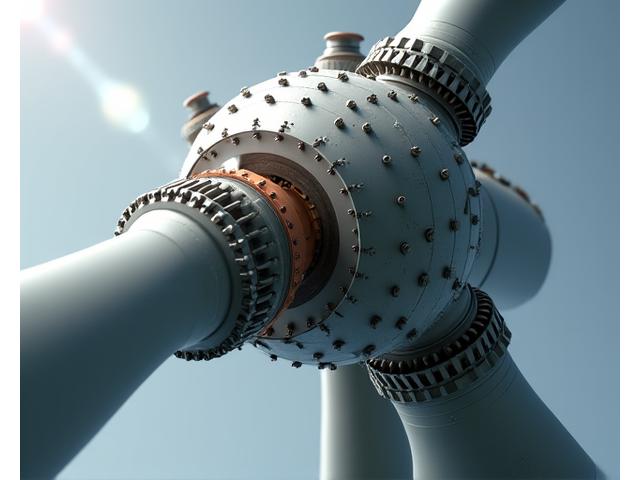

Hub Assemblies & Pitch Systems

Critical for blade angle optimization, our hub assemblies and pitch systems are engineered for maximum torque transfer and precise adjustment. We offer fully integrated hydraulic and electric pitch control solutions, ensuring peak efficiency.

- High-Precision Pitch Control

- Robust Bearing Solutions

- Advanced Lubrication & Cooling

Tower Internals & Structures

We produce and pre-assemble tower internals, including access ladders, platforms, cabling infrastructure, and critical structural bracing components. Our modular designs facilitate rapid on-site assembly and long-term durability.

- Modular Pre-Fabricated Sections

- Corrosion-Resistant Coatings

- Integrated Safety & Access Systems

Precision Machined & Cast Parts

From complex gearbox components to specialized fasteners and custom castings, our machining capabilities ensure every part meets the stringent demands of wind energy applications for reliability and performance.

- Multi-Axis CNC Machining

- Advanced Alloy Casting

- Rapid Prototyping Services

Custom Solutions & Prototyping

Beyond standard components, SolsticeForge specializes in custom manufacturing engineered to your unique specifications. Our rapid prototyping and R&D capabilities accelerate your new product development cycles.

- Collaborative Design Partnership

- Advanced Simulation & Testing

- Scalable Production Readiness

Advanced Manufacturing Techniques

SolsticeForge integrates cutting-edge processes and material science to achieve unparalleled precision and efficiency in wind component production. Our facilities feature the latest in automation and quality control.

Composite Blade RTM

Utilizing Vacuum-Assisted Resin Transfer Molding (VARTM), we achieve superior fiber-to-resin ratios, significantly enhancing blade strength, stiffness, and fatigue resistance while reducing weight.

Multi-Axis CNC Machining

Our state-of-the-art multi-axis CNC machines deliver micron-level precision for complex metallic components, ensuring perfect fit and optimal performance for nacelle and hub assemblies.

Integrated Quality Control

Every component undergoes rigorous testing, including ultrasonic, X-ray, and vibration analysis, ensuring superior structural integrity and compliance with the most demanding industry standards.

IEC 61400 Compliance & Quality Assurance

Quality is non-negotiable at SolsticeForge. Our manufacturing processes and output are meticulously aligned with the stringent requirements of IEC 61400 series standards for wind turbines, assuring reliability and safety for every component.

-

International Standards Adherence

Full compliance with IEC 61400-1, -2, -3, and related standards covering design requirements, small wind turbines, and offshore wind turbine design.

-

Rigorous Material & Fatigue Testing

Comprehensive material testing, structural analysis, and accelerated fatigue testing ensure components withstand extreme operational conditions over their lifespan.

-

ISO 9001:2015 Certified QM System

Our quality management system is ISO 9001:2015 certified, guaranteeing consistent processes, continuous improvement, and robust traceability for every product.

Strategic OEM Partnership Advantages

Partnering with SolsticeForge means gaining a strategic edge. Our domestic manufacturing capabilities provide unparalleled benefits, from compliance and cost savings to supply chain resilience and engineering excellence.

-

Buy America Compliance

Ensure your wind projects meet all domestic content requirements for federal incentives and government contracts with our USA-made components.

-

Reduced Supply Chain Risk

Mitigate geopolitical and logistical risks with a resilient, localized supply chain. Experience faster lead times and just-in-time delivery.

-

Collaborative Engineering Support

Access our expert engineering teams for design optimization, value engineering, and custom component development, ensuring maximum performance and manufacturability.

Production Capacity & Delivery Schedules

SolsticeForge operates with robust production capacities designed to meet the demands of even the largest onshore wind projects. Our agile planning and advanced logistics ensure timely delivery and seamless integration into your project timelines.

Optimized Throughput

Our Los Angeles facilities are equipped with automated lines capable of producing a significant volume of blades, nacelle components, and internal structures annually. We continuously invest in technology to scale with market demand.

- Advanced robotics for high-speed composite lay-up.

- Multiple large-scale machining centers operating 24/7.

- Dedicated assembly bays for complete sub-systems.

Reliable Delivery Schedules

We work closely with our partners to establish realistic and reliable delivery timelines. Our internal logistics and strategic port proximity in Los Angeles ensure efficient shipping and reduced lead times for domestic projects.

- Just-in-Time (JIT) delivery for optimized inventory.

- Transparent production tracking and proactive updates.

- Dedicated account management for project coordination.

Components Powering Major Wind Projects

Our commitment to excellence is proven in the field. SolsticeForge components are integrated into significant onshore wind installations across the nation, contributing to reliable and efficient renewable energy generation.

Midwest Wind Energy Project

Provided 150 custom-engineered blade sets for a 300 MW onshore wind farm. Delivered on schedule, contributing to significant energy output for 150,000 homes annually.

- Blades, Nacelle Housings

- Iowa, USA

Texas Frontier Wind Development

Supplied critical precision machined hub components and tower internals for 80 next-generation turbines. Achieved a 15% reduction in installation time due to modular design.

- Hubs, Tower Internals

- West Texas, USA

Pacific Northwest Resilience Project

Provided energy storage system integration components and specialized microgrid control units, enabling grid stability for a remote community in challenging terrain.

- Microgrid Components, Custom Subassemblies

- Oregon, USA

Custom Component Engineering & Manufacturing

Do you have unique specifications or a complex wind energy challenge? Our dedicated engineering team is ready to provide a detailed consultation, offering design optimization, feasibility analysis, and tailored manufacturing solutions.

- Prototype Development & Testing

- Value Engineering for Cost Efficiency

- Long-Term Supply Agreement Structuring

- Comprehensive Manufacturing Feasibility Studies